Is all Standing Seam Roofing created equal?

If you are considering purchasing a Standing Seam roof there are a few things that you should be aware of and watch for. Not all Standing Seam roofing is created equal so here at Classic Metals, we strive to provide you with all the information you need to make a informed decision.

Material Substrate

The substrate that steel panels are made of, is an integral part of the product and will affect the longevity of the steel. The two most common Substrates are Galvanized and Galvalume. Galvanized is basically steel that is hot dipped in zinc, and one of the main drawbacks is that the zinc coating can easily be scratched off. Galvalume is eGalvalume Steel can be expected to provide at least TWICE the service life of traditional zinc-coatings of similar coating thickness under the same exposure conditions. This has been proven by actual exposure tests using flat coupon samples, conducted over 36 years in the U.S.A. and 15 years in Canada. These tests show that Galvalume has at least TWICE the service life versus Galvanized.

Trim Thickness

When you are discussing options with your installer or steel supplier, be sure and confirm that they manufacture the trims that you will need, out of the same steel as the panels. This is a common area that suppliers can cut costs and use 29 gauge trims on a 26 gauge roof for example. This is not only a unnecessary cutting of corners, it can lead to uneven fading of trims verses panels.

Oil Canning

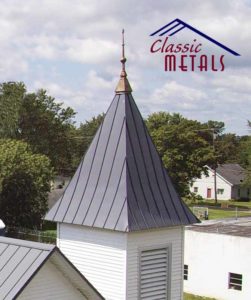

Oil Canning in metal roofing is not a structural problem or a cause for rejection, however most manufacture’s and installers try to avoid it if possible. Material thickness and type of material can contribute to oil canning and install procedures also play a part, but panel design and machine settings play the greatest role. At Classic Metals we pride ourselves in maintaining high quality machinery that produce panel quality that is second to none. The picture of the two roofs to the right, show the difference between a panel that Classic Metals manufactured and a competitor. Both pictures were taken on buildings that were exactly the same, and less than 50 feet from each other.

Don’t settle for a Standing Seam Roof that is less than it could be, give us a call today and we will show you the difference.

The information provided is for reference only and may change without notice

county home. The customer was looking at several colors and options that were available and was undecided on what would be best. After some consultation with a local installer the 24 gauge 16″ wide

county home. The customer was looking at several colors and options that were available and was undecided on what would be best. After some consultation with a local installer the 24 gauge 16″ wide  directly onto the existing shingles. This required a number of custom trims to be made to accommodate the extra coverage that was needed. The design of the home also caused the roof itself to have several unique and challenging quality’s, but the installer rose to the occasion and did a great job.

directly onto the existing shingles. This required a number of custom trims to be made to accommodate the extra coverage that was needed. The design of the home also caused the roof itself to have several unique and challenging quality’s, but the installer rose to the occasion and did a great job. installation, and everything went well and they were installed on the home over the next week. The 24 gauge material that was used comes with a 35year warranty on the paint, and a lifetime manufacture’s warranty so a roof replacement is the last thing the customer needs to worry about.

installation, and everything went well and they were installed on the home over the next week. The 24 gauge material that was used comes with a 35year warranty on the paint, and a lifetime manufacture’s warranty so a roof replacement is the last thing the customer needs to worry about.

job site that we visited a few weeks ago. The existing roofing that was on the home of Dave and Heidi Scherpelz was Galvanized Hand Seamed Standing Seam Roofing. This type of steel roofing has yearly maintenance that is needed in order for the roof to last long term. Every year the seams need to be re-crimped and sealed with a special sealer and the roof need to be inspected for leaks. Over the years some of these steps had been neglected, and the roof was slowly deteriorating.

job site that we visited a few weeks ago. The existing roofing that was on the home of Dave and Heidi Scherpelz was Galvanized Hand Seamed Standing Seam Roofing. This type of steel roofing has yearly maintenance that is needed in order for the roof to last long term. Every year the seams need to be re-crimped and sealed with a special sealer and the roof need to be inspected for leaks. Over the years some of these steps had been neglected, and the roof was slowly deteriorating. would do a great job”.

would do a great job”.

Hochstedler and Sons did a really great job on the installation, and everyone is really pleased with how it turned out. They really took their time and paid attention to the details, and that is really important for a completed job to look its best. Congratulations to Dave and Heidi on a great looking home, and a roofing system that is designed in such a way, that yearly maintenance is now a thing of the past.

Hochstedler and Sons did a really great job on the installation, and everyone is really pleased with how it turned out. They really took their time and paid attention to the details, and that is really important for a completed job to look its best. Congratulations to Dave and Heidi on a great looking home, and a roofing system that is designed in such a way, that yearly maintenance is now a thing of the past.

Karen’s Kids Campus began March 1st 2015 at a different location, and then moved to the current location close to Interstate 71 in early 2016. Classic Metals was involved in manufacturing the Standing Seam for the building that they are currently in and worked closely with the roofing installer. The roofing that was chosen was the weatherlock 16 inch wide panel, manufactured on-site in a 26ga custom red color and it was installed by

Karen’s Kids Campus began March 1st 2015 at a different location, and then moved to the current location close to Interstate 71 in early 2016. Classic Metals was involved in manufacturing the Standing Seam for the building that they are currently in and worked closely with the roofing installer. The roofing that was chosen was the weatherlock 16 inch wide panel, manufactured on-site in a 26ga custom red color and it was installed by

future, however, there was no way to avoid it. Several years after purchasing the home, they realized that the asphalt shingles were deteriorating fast, after being installed for less than 12 years. They attempted to contact the shingle manufacturer for a warranty claim, but were told that because they were not the original owners, the roof was no longer under warranty. As they considered the roofing options that were available, they made contact with Aaron from Quality Roofing, a roofing installer from Big Prairie Ohio. Aaron explained the advantages of a Standing Seam metal roof and the decision was made to install the 16″ Weatherlock Panel in 26 Gauge Slate Gray. The installation went great, and they were very pleased with the final product.

future, however, there was no way to avoid it. Several years after purchasing the home, they realized that the asphalt shingles were deteriorating fast, after being installed for less than 12 years. They attempted to contact the shingle manufacturer for a warranty claim, but were told that because they were not the original owners, the roof was no longer under warranty. As they considered the roofing options that were available, they made contact with Aaron from Quality Roofing, a roofing installer from Big Prairie Ohio. Aaron explained the advantages of a Standing Seam metal roof and the decision was made to install the 16″ Weatherlock Panel in 26 Gauge Slate Gray. The installation went great, and they were very pleased with the final product. One of the things that Gene does currently to stay busy is to take photo’s of the surrounding Amish community, and a number of his photo’s have been used in magazines and newspapers. You can view some of the photo’s that he has taken at

One of the things that Gene does currently to stay busy is to take photo’s of the surrounding Amish community, and a number of his photo’s have been used in magazines and newspapers. You can view some of the photo’s that he has taken at